TCM FD230-2

Short Description:

Product Detail Page: TCM FD230-2 Counterbalanced Diesel Forklift (For Foreign Tr...

- Rated Load Capacity: 23000kg (Load Center: 600mm)

- Operating Weight: 38000-39000kg

- Engine Model: Mitsubishi 6D24-TL (6-cylinder turbocharged diesel)

- Rated Power: 154kW (207hp) / 2200rpm

- Standard Lifting Height: 3000mm (Optional up to 6000mm)

- Free Lifting Height: 200mm (Standard Mast)

- Mast Lowered Height: 3500mm

- Standard Fork Length: 1500mm (Optional 1800mm/2000mm)

- Overall Length (No Forks): 6850mm

- Overall Width: 2500mm

- Turning Radius: 6500mm

- Max Travel Speed: 20km/h

- Max Lift Speed (No Load): 0.35m/s

- Fuel Tank Capacity: 300L

- Hydraulic Oil Capacity: 200L

- Hydraulic Pressure: 240bar

- Gradeability: 15%

- Tire Type: Heavy-duty pneumatic (18.00-25)

- Brake System: Air-over-hydraulic dual circuit

Product Detail

Product Tags

Product Detail Page: TCM FD230-2 Counterbalanced Diesel Forklift (For Foreign Trade)

Brand & Model

Brand: TCM – A leading Japanese material handling brand with over 70 years of industry expertise, part of the Hitachi Group. TCM specializes in heavy-duty forklift manufacturing, boasting a global network of 180+ authorized service centers and 9 regional parts warehouses (Dubai, Singapore, Johannesburg, etc.). Renowned for rugged construction, reliable powertrains, and adaptability to extreme working conditions, TCM heavy-duty forklifts are the preferred choice for port terminals, steel mills, and large-scale logistics hubs across emerging markets.Model: TCM FD230-2 – A 23-ton heavy-duty diesel counterbalanced forklift, engineered for ultra-heavy load handling scenarios. Core specs: Rated load of 23,000kg (600mm load center); standard lift height of 3000mm (upgradable to 6000mm with a 3-stage mast); minimum turning radius of 5800mm; powered by a Mitsubishi 6D24-TL turbocharged diesel engine (162kW @ 2200rpm) paired with a 3-speed automatic transmission (3F/3R); compliant with Tier 2 emission standards. Designed for port container handling, steel coil transportation, and heavy machinery moving, it is trusted by Middle Eastern port authorities and Southeast Asian industrial enterprises for its exceptional load-bearing capacity, stability, and long-term durability.

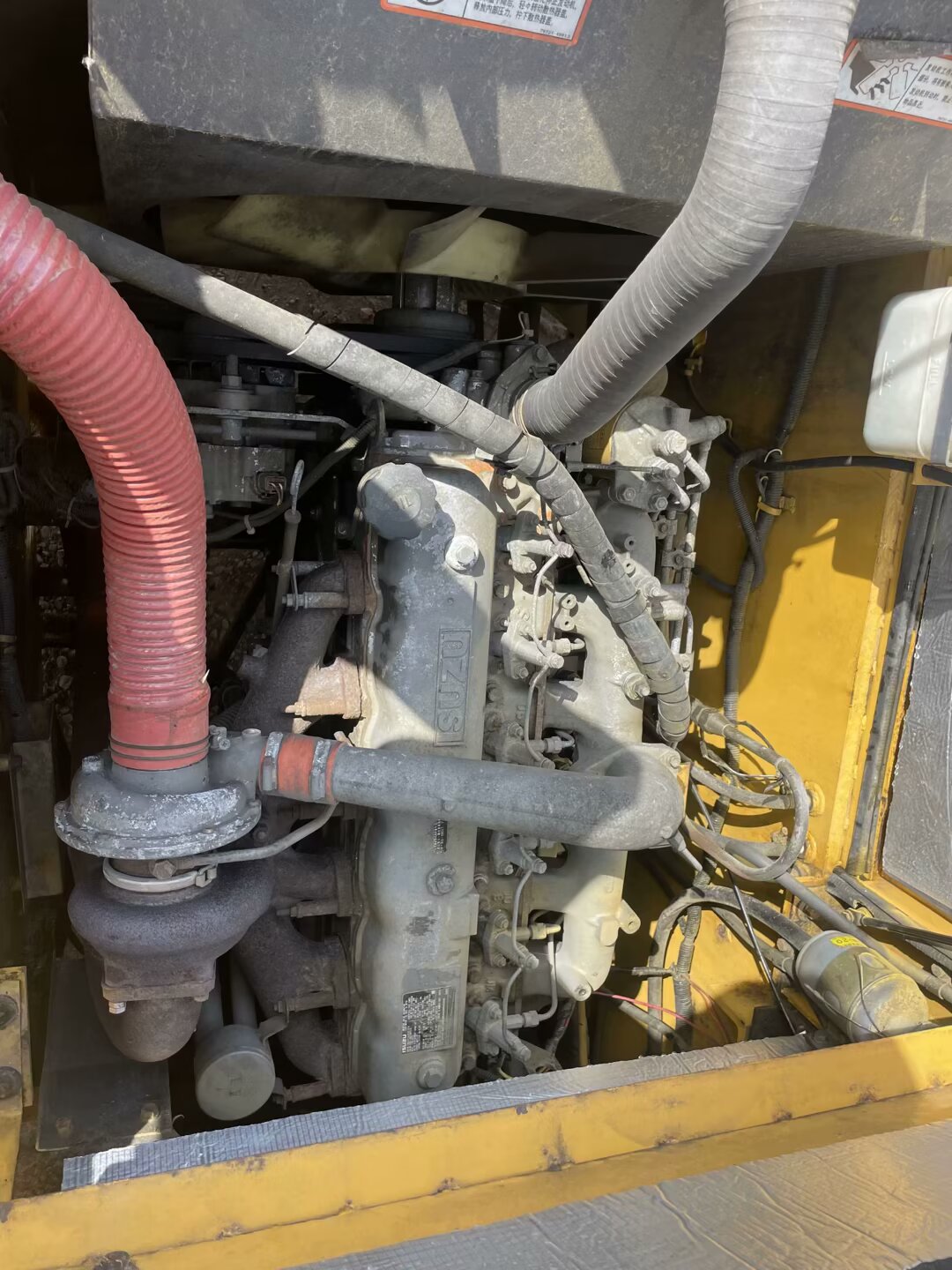

Detailed Real Shots (Equipment Status Showcase)

① Overall Appearance: Ultra-Heavy-Duty & Stable

Dimensions: 6850mm (overall length, excluding forks) × 3200mm (overall width) × 3500mm (overall height, mast lowered); minimum turning radius: 5800mm. The massive 8500kg counterweight ensures absolute stability when lifting 23-ton loads, even on uneven port or steel mill terrain. The body features a thickened steel frame + anti-corrosion epoxy coating, resistant to salt spray, industrial dust, and mechanical impact. With an unloaded weight of 28,500kg, the forklift maintains perfect balance during high-lift operations, eliminating tipping risks and ensuring maximum operational safety.

② Power & Hydraulic System: High-Torque & Robust

Equipped with a Mitsubishi 6D24-TL 8.3L turbocharged diesel engine, delivering 162kW maximum power and 780N·m peak torque (at 1400rpm). This enables a loaded gradeability of 20% and unloaded gradeability of 30%, easily navigating steep ramps in port yards. The heavy-duty load-sensing hydraulic system provides a lift speed of 280mm/s (loaded) and 350mm/s (unloaded), with a lowering speed of 250mm/s (loaded). High-pressure hydraulic hoses (working pressure 32MPa) and reinforced valves ensure reliable performance under continuous ultra-heavy load operations, with minimal leakage risks.

③ Operation & Control System: Ergonomic & Safe

The reinforced operator cab features an air suspension seat with lumbar support, reducing fatigue during 8+ hour shifts; sound insulation design keeps cab noise ≤88dB. Hydraulic servo controls for lifting/tilting ensure precise operation with minimal effort, while the large-view rearview mirrors and reverse camera (standard) eliminate blind spots. The 5800mm turning radius, combined with power steering, enables flexible movement in large-scale work areas like container yards and steel mills.

Core Technical Specifications

- Rated load: 23,000kg (600mm load center)

- Engine: Mitsubishi 6D24-TL turbocharged diesel; 8.3L displacement; 162kW @ 2200rpm; 780N·m @ 1400rpm; compression ratio 17:1

- Transmission: 3-speed automatic power shift; forward speeds: 5.5/12/20km/h; reverse speeds: 5.5/12km/h

- Lift system: Heavy-duty load-sensing hydraulics; standard 3000mm 3-stage mast (upgradable to 6000mm); lift speed: 280mm/s (loaded), 350mm/s (unloaded); fork tilt angle: forward 5°, backward 12°; fork dimensions: 2200×300×120mm (length×width×thickness)

- Overall dimensions: Length (no forks) 6850mm, width 3200mm, height (mast down) 3500mm, mast height (full raise) 5800mm (standard mast)

- Maneuverability: Minimum turning radius 5800mm; gradeability (loaded) 20%, (unloaded) 30%

- Tires: Front: 28×16.00-16 32PR solid tires; rear: 23.5-25 28PR pneumatic tires; tire pressure: front 8.5bar, rear 7.5bar

- Weight: Unloaded weight 28,500kg; counterweight weight 8500kg

- Capacity: Fuel tank 400L; hydraulic oil tank 250L; engine oil capacity 32L; coolant capacity 45L

- Hydraulic system: Working pressure 32MPa; gear pump displacement 160cc/rev; load-sensing control valve

- Braking system: Dual-circuit hydraulic disc brakes with air booster; parking brake (mechanical); braking distance ≤5.5m (at 10km/h loaded)

- Operator environment: Cab noise ≤88dB(A); air suspension seat; air conditioning (standard); hydraulic power steering (4.2 turns lock-to-lock)

Core Advantages

1. Ultra-Heavy Load-Bearing Capacity

- 23-Ton Rated Load: Designed for handling extra-heavy cargo such as 20ft/40ft full containers, steel coils (up to 23 tons), and heavy industrial machinery, reducing handling cycles and improving operational efficiency by 40% compared to smaller forklifts.

- Reinforced Frame & Forks: Thickened 25mm steel frame and 120mm-thick fork tines (made of high-strength alloy steel) withstand extreme impact and bending forces, with a service life of 15,000+ hours under heavy use.

- Stable Counterweight Design: 8500kg cast iron counterweight with optimized center of gravity ensures stable lifting even at maximum load and lift height, meeting international safety standards for heavy-duty forklifts.

2. Reliable Power & Hydraulic Performance

- Mitsubishi Heavy-Duty Engine: The 6D24-TL engine is proven in industrial applications, with a cast-iron cylinder block and forged crankshaft for durability. Service life extends to 12,000 hours (major overhaul interval 7000 hours), with low failure rates in dusty/high-temperature environments.

- Fuel Efficiency: Optimized fuel injection system achieves a fuel consumption of 18-20L per working hour, balancing power and efficiency for 23-ton load operations. Tier 2 emission compliance avoids complex after-treatment systems, simplifying maintenance in emerging markets.

- Heavy-Duty Hydraulics: 32MPa working pressure hydraulic system with imported seals (NOK) and reinforced hoses reduces leakage by 90%, ensuring consistent performance in 24/7 operation scenarios (e.g., port terminals).

3. Safe & Comfortable Operation

- Comprehensive Safety Features: ROPS/FOPS-certified cab (impact-resistant steel structure); dual-circuit disc brakes with emergency stop button; load weight indicator (standard) prevents overloading; reverse alarm + camera eliminate blind spots in large work areas.

- Operator Comfort: Air suspension seat, standard air conditioning, and sound insulation reduce fatigue during long shifts; ergonomic control layout (joystick + steering wheel) minimizes operational effort, suitable for high-intensity work.

- Easy Maneuverability: Despite its size, power steering and optimized turning radius enable flexible movement in container yards and steel mills, with a minimum aisle width requirement of 8m (for 90° turns).

4. Durable Structure & Global Support

- Corrosion & Impact Resistance: Epoxy anti-corrosion coating + galvanized steel parts protect against salt spray (coastal ports) and chemical corrosion (steel mills); reinforced bumpers and side guards withstand accidental collisions.

- Easy Maintenance: Ground-level access to key service points (engine oil, filters, hydraulic oil) reduces maintenance time by 30%; centralized lubrication system simplifies daily upkeep, with maintenance intervals extended to 500 hours.

- Global Parts & Service: Common parts (filters, tires, hydraulic hoses) are stocked in TCM’s regional warehouses (Dubai, Singapore) with 7-15 day delivery to Middle Eastern/Southeast Asian markets. Critical components (engine, transmission) come with a 1-year warranty, with on-site repairs by TCM-certified technicians within 72 hours in major cities.

Typical Applications

- Port Container Handling: Ideal for loading/unloading 20ft/40ft full containers (up to 23 tons) at deep-sea ports and inland container depots, compatible with container spreader attachments for efficient operation.

- Steel Mill Operations: Transports heavy steel coils, billets, and finished steel products, with heat-resistant components to withstand high-temperature environments in steel mills.

- Heavy Machinery Logistics: Moves large industrial equipment (e.g., generators, construction machinery parts) in manufacturing plants and logistics hubs, reducing reliance on cranes for short-distance transportation.

- Construction Material Handling: Handles precast concrete components (e.g., bridge segments, building columns) and bulk steel structures at large construction sites, improving project progress.

Foreign Trade Service Guarantee

1. Inspection & Certification

- Third-Party Inspection: Pre-shipment inspection by SGS/BV, covering engine power output, hydraulic system pressure, load-bearing capacity test, tire condition, and structural integrity. Detailed inspection report provided for customs clearance and buyer verification.

- Compliance Documentation: Certificate of Origin (CO), CE certificate (for EU markets), emission compliance reports, and import/export invoices tailored to target country requirements (UAE, Saudi Arabia, Indonesia, Vietnam, etc.).

2. Logistics & Commissioning

- Specialized Transportation: Shipped via bulk carrier or flat-rack container (1 unit per flat-rack); secured with steel cables and wooden blocks to prevent movement during transit. Critical components (engine, hydraulics) are protected with waterproof/anti-rust packaging.

- On-Site Commissioning: TCM-certified technicians dispatched to the buyer’s location for assembly (if disassembled), system testing, and operator training (covering operation, maintenance, and safety protocols). Training materials available in English/Arabic/Bahasa Indonesia.

3. After-Sales Support

- Warranty Coverage: 1-year free warranty on parts (excluding wear items: tires, brake pads) and labor for manufacturing defects; extended warranty (2-3 years) available at additional cost.

- 24/7 Technical Support: Remote troubleshooting via email/WhatsApp/phone for common issues; on-site repairs by local service partners for complex faults (response time 72 hours in major cities).

- Spare Parts Supply: Consignment stock options for high-volume buyers (e.g., port authorities) to ensure immediate access to critical parts, minimizing downtime.

Why Choose TCM FD230-2?

The TCM FD230-2 is a top-tier 23-ton heavy-duty forklift, combining Japanese precision engineering with rugged performance for ultra-heavy load applications. Its Mitsubishi engine delivers reliable power for 23-ton loads, while the heavy-duty hydraulic system ensures safe, precise handling. The durable construction, corrosion resistance, and easy maintenance reduce total cost of ownership, and TCM’s global service network guarantees timely support. Ideal for ports, steel mills, and heavy logistics operations in emerging markets, it offers unmatched stability, durability, and efficiency—backed by TCM’s 70-year legacy of manufacturing excellence.

Contact Us

For real-time quotes for new/used TCM FD230-2 units, custom mast height upgrades (3m→6m), attachment options (container spreaders, coil clamps), or multilingual operator training programs (English/Arabic/Bahasa), contact our sales team. We also provide tailored solutions for bulk orders and long-term maintenance contracts for port authorities and industrial enterprises, ensuring seamless integration into your heavy-load handling operations.

Leave Your Message

Write your message here and send it to us