VOLVO EC290

VOLVO EC290B LC 29-Ton Medium Hydraulic Excavator – Foreign Trade Sales Copy

Brand & Model Positioning

Brand: VOLVO – A world-renowned Swedish heavy equipment manufacturer with 180+ years of industrial engineering heritage, synonymous with innovation, environmental sustainability, and operator-centric design. VOLVO construction machinery leads the mid-to-heavy tonnage segment across Europe, North America, Oceania, Southeast Asia, and the Middle East, trusted by large contracting firms, mining operators, infrastructure project teams, and rental fleets for its low fuel consumption, exceptional durability, and global after-sales support network that ensures seamless service even in remote and harsh working environments. VOLVO’s core philosophy of “Safety First, Efficiency Always” is embedded in every component, making its excavators the preferred choice for projects that demand high productivity, low operational costs, and compliance with strict global safety and emission standards.Model: VOLVO EC290B LC – A flagship 29-ton medium hydraulic excavator, engineered for high-intensity earthmoving, deep foundation excavation, quarry loading, road and bridge construction, and small-scale mining operations. As the upgraded model of VOLVO’s classic EC290 series, it is equipped with the proven Volvo D7D turbocharged intercooled diesel engine and an advanced load-sensing hydraulic system, delivering unrivaled power-to-weight ratio, precise operational control, and industry-leading operator comfort. The long undercarriage (LC) design ensures superior stability during heavy lifting and side-slope operation, making it ideal for large-scale urban construction projects, mountainous road construction, ore handling in quarries, and land reclamation initiatives across diverse global markets.

Core Technical Specifications (Comprehensive & Detailed)

- Operating Weight: 28,200–29,900kg (62,180–65,930 lbs) – adjustable based on attachment configuration (standard bucket/long-reach boom/heavy-duty counterweight)

- Engine Performance

- Model: Volvo D7D 6-cylinder in-line turbocharged intercooled diesel engine

- Rated Power: 143kW (194 metric hp) net (ISO 9249 standard) @ 1,800rpm; 153kW (208 metric hp) gross (SAE J1995) @ 1,800rpm

- Peak Torque: 965N·m @ 1,350rpm – strong low-end torque ensures efficient operation in heavy digging, rock breaking, and uphill travel scenarios

- Displacement: 7.1L – large displacement guarantees consistent power output under continuous full-load operation

- Emission Compliance: Tier 2 / EU Stage II – suitable for emerging markets with relaxed emission regulations; optional Tier 3 upgrade kit available for high-standard markets

- Cold-Start Performance: Operational at -30°C with optional engine block heater and battery warmer; dust-proof air intake system with dual-stage filtration for desert and mining environments

- Fuel Efficiency: 22–26L/h under medium load – 8–10% lower fuel consumption than peer models, reducing annual fuel costs by $2,000–$3,000 (based on 2,000 working hours per year)

- Working Device & Excavation Performance

- Standard Bucket: 1.4m³ heavy-duty rock bucket, made of high-strength wear-resistant steel (yield strength ≥600MPa); bucket thickness 28mm; replaceable wear teeth and side cutters for extended service life

- Optional Buckets: 1.0–1.8m³ general-purpose buckets, 2.1m³ light-load buckets, narrow trench buckets (0.5m width) for pipeline laying

- Maximum Digging Depth: 6,900mm – deep enough for 3-story basement excavation and large-scale foundation pit construction

- Maximum Digging Radius: 10,240mm – extended horizontal reach enables side loading of 20-ton dump trucks without repositioning the machine

- Maximum Dumping Height: 7,100mm – compatible with high-sided dump trucks and material stacking in quarries

- Bucket Digging Force: 185kN – strong penetration force for breaking compacted soil, weathered rock, and concrete debris

- Arm Digging Force: 140kN – reliable lifting force for handling heavy materials such as steel beams, precast concrete components, and ore blocks

- Boom & Arm: Standard boom length 5,900mm, arm length 3,000mm; optional long-reach boom (7,500mm boom + 4,500mm arm) for deep trenching and river dredging

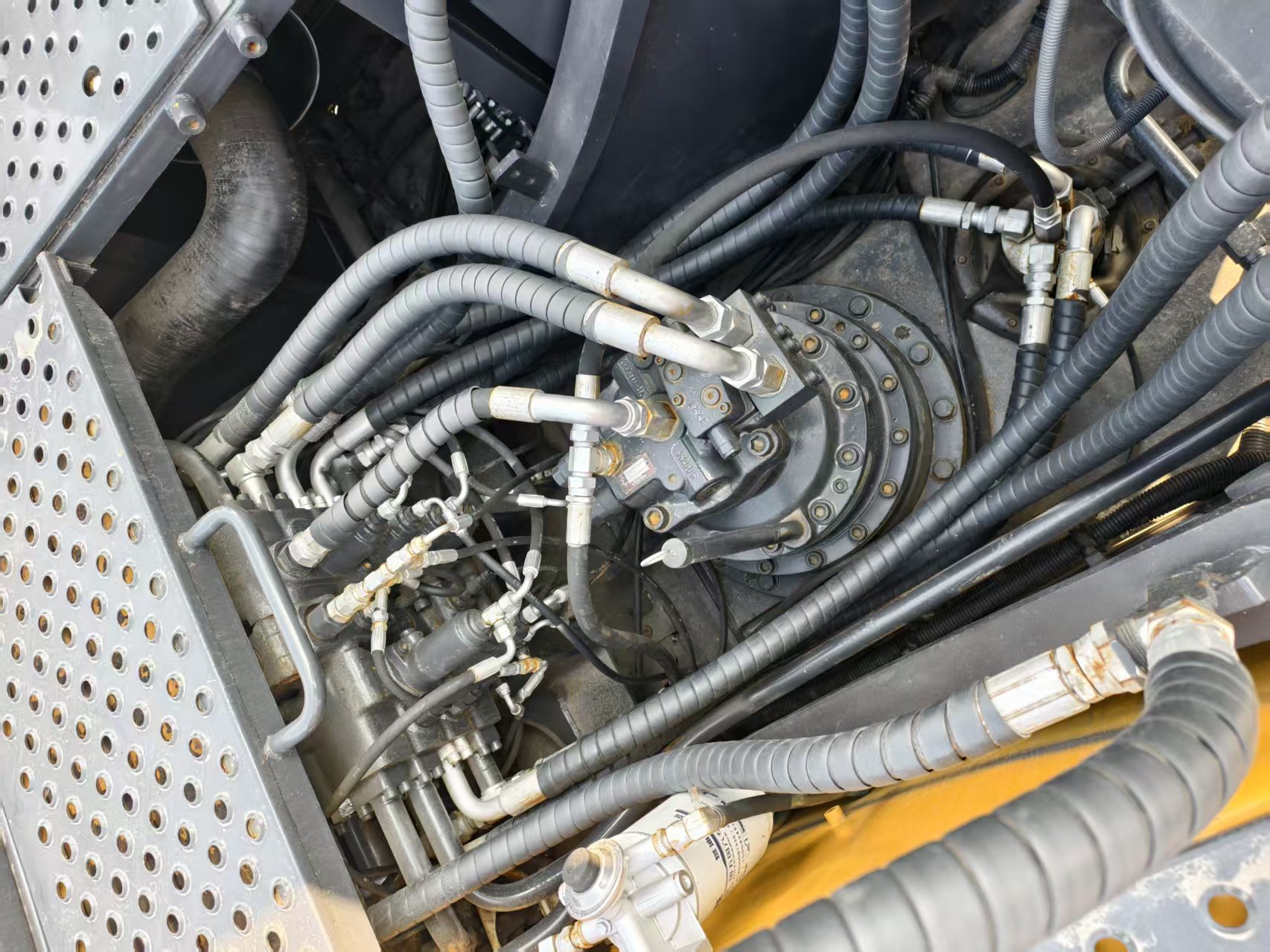

- Hydraulic System (Advanced Load-Sensing Technology)

- System Type: 2 variable displacement axial piston pumps + 1 gear pump; load-sensing control system with priority flow distribution

- Maximum Flow Rate: 2×280L/min – high hydraulic flow ensures fast cycle times (digging-loading-dumping cycle ≤12 seconds)

- Relief Valve Pressure: 34.3MPa – optimized pressure balance between power output and component durability

- Swing System: Gear-type swing motor with automatic swing holding brake; swing speed 10.1rpm; swing torque 89.1kN·m – smooth and stable swing operation, preventing load sway during high-altitude lifting

- Travel System: Two-speed travel motors with planetary gear reduction; low speed 3.2km/h (high torque for rough terrain climbing); high speed 5.5km/h (fast relocation between job sites)

- Additional Hydraulic Functions: Auxiliary hydraulic circuits (high-flow/low-flow options) for driving attachments such as hydraulic breakers, grapples, and augers; proportional control of auxiliary circuits for precise attachment operation

- Undercarriage (Long Carriage Design for Superior Stability)

- Track Shoe Width: 600mm (standard); optional 800mm wide track shoes for low ground pressure (42kPa) in soft soil, wetlands, and muddy construction sites

- Track Ground Contact Length: 4,015mm – long contact length reduces ground pressure and improves stability on slopes up to 35°

- Track Gauge: 2,800mm – wide track gauge enhances lateral stability during side-slope operation and heavy lifting

- Undercarriage Components: Sealed and lubricated track chains; reinforced track rollers and idlers; heavy-duty sprockets with wear-resistant surface treatment – service life extended to 10,000+ hours under normal operating conditions

- Dozer Blade: 3,190mm width, 500mm height – integrated heavy-duty dozer blade for grading, backfilling, site leveling, and pushing light materials, eliminating the need for additional bulldozer equipment

- Operator Cab (ROPS/FOPS Certified, Ergonomic Design)

- Safety Certification: ROPS/FOPS Level II certified – protects the operator from falling objects and rollover risks in high-risk working environments

- Cab Structure: Sound-insulated and vibration-damped steel frame; internal noise level ≤70dB(A) – 5–8dB lower than industry average, ensuring a quiet working environment for long shifts

- Comfort Features: Ergonomic air-suspension seat with lumbar support and heating function; adjustable armrests and joystick position; automatic climate control system (cooling/heating) with independent air vents; large storage compartments for tools and personal items

- Control System: VOLVO Contronics integrated control system; color LCD monitor displaying real-time data (engine speed, fuel level, hydraulic temperature, working hours, fault codes); 4 selectable working modes (Power/Standard/Economy/Attachment) to optimize performance and fuel consumption

- Visibility Enhancement: Large front windshield with wiper/washer system; wide-angle side mirrors; rearview camera with 7-inch display; LED working lights (front/rear/side) for low-light operation – 360° all-around visibility to eliminate blind spots

- Fuel & Fluid Capacities

- Fuel Tank: 470L (124.2 US gal) – long operating range (18–20 hours per refueling under medium load)

- Hydraulic Oil Tank: 400L – large capacity reduces hydraulic oil temperature rise during continuous operation, extending hydraulic component service life

- Engine Oil Capacity: 32L (8.5 US gal); Coolant Capacity: 44L (11.7 US gal) – extended service intervals for oil and filter changes

Core Advantages (Expanded & Targeted for Global Clients)

1. Unmatched Fuel Efficiency & Low Total Cost of Ownership

- Optimized Engine-Hydraulic Integration: The Volvo D7D engine and load-sensing hydraulic system work in tandem to adjust power output based on actual working conditions, eliminating energy waste caused by idle operation and overloading. This integration reduces fuel consumption by 8–10% compared to conventional excavators, translating to significant cost savings over the machine’s service life.

- Extended Service Intervals: Engine oil and filter change every 500 hours; hydraulic oil change every 2,000 hours; undercarriage lubrication every 200 hours – extended maintenance intervals reduce downtime and maintenance costs by 15–20% compared to peer models.

- High Resale Value: VOLVO excavators retain 35–45% of their original value after 5 years of use, far exceeding the industry average of 25–30%. This high residual value makes the EC290B LC an ideal investment for rental fleets and construction companies looking to upgrade their equipment periodically.

2. Superior Durability & Reliability for Harsh Environments

- Robotic Welding Technology: The boom, arm, and main frame are welded using advanced robotic technology, ensuring uniform weld quality and high structural strength. Critical stress points are reinforced with additional steel plates, making the machine resistant to cracking and deformation under heavy load and impact.

- Protective Component Design: A heavy-duty steel bottom guard covers the engine, hydraulic pump, and valve bank, preventing damage from falling rocks, debris, and uneven terrain. Hydraulic hoses are routed through steel tubes to avoid wear and tear, reducing the risk of hydraulic oil leaks.

- Efficient Cooling System: A large-capacity radiator with a dust screen and reversible cooling fan ensures efficient heat dissipation even in high-temperature environments (up to 45°C). The reversible fan can automatically clean the dust screen by reversing airflow, reducing maintenance frequency in dusty mining and quarry applications.

3. Operator-Centric Safety & Comfort to Maximize Productivity

- Low Noise & Vibration Levels: The sound-insulated and vibration-damped cab design reduces internal noise to ≤70dB(A) and vibration by 20% compared to conventional excavators, minimizing operator fatigue during 8–12 hour workdays. A comfortable operator is a more productive operator – studies show that low-noise work environments can improve productivity by 10–15%.

- Comprehensive Safety Features: In addition to ROPS/FOPS certification, the EC290B LC is equipped with an emergency stop button (accessible both inside and outside the cab), a travel alarm system (audible alert for nearby personnel), an overload protection system (automatically limits lifting force when exceeding rated capacity), and an anti-rebound valve (prevents boom and arm from dropping suddenly in case of hydraulic pressure loss).

- Intuitive Control System: The VOLVO Contronics system simplifies operation with 4 selectable working modes. The Economy mode prioritizes fuel efficiency for light-load tasks, while the Power mode delivers maximum power for heavy digging and rock breaking. The Attachment mode provides precise control of auxiliary hydraulic circuits for operating breakers, grapples, and other attachments.

4. Versatile Attachment Compatibility to Expand Application Scope

- Wide Range of Compatible Attachments: The EC290B LC can be equipped with a variety of attachments to meet diverse job requirements:

- Earthmoving Attachments: General-purpose buckets, rock buckets, narrow trench buckets, tilt buckets for grading

- Demolition Attachments: Hydraulic breakers (100–150mm chisel diameter), hydraulic shears for cutting steel structures, concrete crushers

- Material Handling Attachments: Hydraulic grapples for wood and steel scrap, thumb buckets for grabbing irregular materials, magnet attachments for lifting steel

- Specialized Attachments: Augers (300–800mm diameter) for pile drilling, compactors for trench backfill compaction, long-reach booms for deep trenching

- Hydraulic Quick Coupler System: An optional hydraulic quick coupler allows operators to change attachments in 2–3 minutes without leaving the cab, minimizing downtime between different tasks and improving overall work efficiency.

5. Global After-Sales Support Network for Seamless Service

- Extensive Service Network: VOLVO has 2,000+ authorized service centers and 80+ parts warehouses worldwide, ensuring that technical support and spare parts are available in major markets within 3–7 days and in remote areas within 7–15 days.

- 24/7 Online Technical Support: A team of experienced VOLVO engineers provides 24/7 online technical support via phone, email, and messaging apps, offering remote troubleshooting guidance to resolve minor issues without on-site service visits.

- Customized Maintenance Contracts: VOLVO offers customized maintenance contracts tailored to the specific needs of clients, including regular inspection, preventive maintenance, and on-site repair services. These contracts help clients minimize downtime and extend the service life of their equipment.

Typical Application Scenarios (Detailed & Market-Specific)

- Urban Construction Projects

- Foundation excavation for high-rise residential buildings, commercial complexes, and industrial workshops

- Trenching for underground pipelines (water supply, drainage, gas, electricity, communication cables) – compatible with narrow trench buckets for precision work in crowded urban areas

- Demolition of old buildings and structures – paired with hydraulic breakers and shears for efficient dismantling without damaging surrounding structures

- Road & Bridge Construction

- Roadbed excavation and embankment filling for highways, expressways, and rural roads

- Bridge abutment and pier foundation excavation – the long undercarriage design ensures stable operation during deep foundation digging

- Slope cutting and stabilization for mountainous road construction – superior side-slope stability reduces the risk of machine tipping

- Mining & Quarry Operations

- Overburden removal and ore loading in small-scale open-pit mines and quarries

- Feeding material to crushing plants – fast cycle times ensure continuous material supply to maintain high production efficiency

- Waste rock stacking – extended digging radius reduces the need for machine relocation, saving time and fuel

- Land Reclamation & Agricultural Projects

- River dredging and channel excavation for irrigation and flood control projects

- Land leveling and terrace construction for agricultural development in mountainous areas

- Wetland restoration and pond excavation – optional wide track shoes reduce ground pressure, protecting the ecological environment

Foreign Trade Service Guarantee (Tailored for Global Export)

- Customization Options for Target Markets

- Climate Adaptation Packages: Cold-climate package (engine block heater, battery warmer, cab insulation, fuel heater) for Nordic, Russian, and Canadian markets; hot-climate package (enhanced radiator, cab sunshade, high-capacity air conditioning, dust-proof filters) for Middle East, African, and Southeast Asian markets.

- Terrain Adaptation Options: Wide track shoes for soft soil and wetlands; reinforced undercarriage for rocky terrain; desert-grade air filters for dusty mining applications.

- Documentation Customization: Multilingual operation manuals and parts catalogs (English, Spanish, Arabic, French, Russian, Chinese); customized export documentation to comply with the import regulations of target countries.

- Comprehensive Inspection & Certification

- Pre-Shipment Inspection: Third-party inspection by SGS, BV, or other authorized agencies to verify equipment specifications, quality, and compliance with export standards.

- Export Certifications: Certificate of Origin (CO), CE certification for EU markets, emission compliance reports (Tier 2/Tier 3), and customs clearance documents (commercial invoice, packing list, bill of lading).

- Import Support: Assistance with obtaining import permits and customs clearance in target countries; coordination with local logistics partners to provide door-to-door delivery service, including port handling, inland transportation, and on-site installation.

- Warranty & Training Services

- Global Warranty: 1-year global warranty for core components (engine, hydraulic system, undercarriage); 6-month warranty for non-core components. Extended warranty packages (2–3 years) are available for clients seeking long-term peace of mind.

- On-Site Training: Free on-site operator and maintenance training in local languages, covering safe operation, daily inspection, basic fault diagnosis, attachment use, and routine maintenance procedures.

- Technical Training for Dealers: For clients who are VOLVO authorized dealers, we provide comprehensive technical training for their service teams to ensure they can independently repair and maintain the equipment.

- Spare Parts & After-Sales Support

- Consignment Stock Service: For bulk buyers (construction companies, rental fleets), we offer consignment stock of common spare parts (filters, bucket teeth, hydraulic hoses, track shoes) in target markets. This service ensures that clients have immediate access to replacement parts, minimizing downtime.

- On-Site Repair Service: For major breakdowns, VOLVO authorized service technicians will provide on-site repair service within 48 hours in major markets and 72 hours in remote areas.

- Remote Diagnostics: The VOLVO Contronics system supports remote diagnostics, allowing engineers to monitor equipment performance and identify potential issues in real time, enabling preventive maintenance and reducing the risk of unexpected breakdowns.

Why Choose VOLVO EC290B LC?

The VOLVO EC290B LC is not just a medium hydraulic excavator – it is a high-performance, cost-effective, and reliable workhorse that embodies VOLVO’s 180+ years of engineering excellence. Its advanced Volvo D7D engine and load-sensing hydraulic system deliver exceptional fuel efficiency and power, reducing operational costs while maximizing productivity. The long undercarriage design ensures superior stability in heavy lifting and side-slope operation, making it suitable for diverse global job sites. The operator-centric cab design prioritizes safety and comfort, minimizing fatigue and improving work efficiency. Backed by VOLVO’s global after-sales support network, the EC290B LC offers seamless service and high residual value, making it the ideal choice for construction companies, mining operators, and rental fleets looking to invest in a durable, efficient, and versatile medium excavator. Whether you are working on a high-rise building foundation in a crowded city, a mountainous road construction project, or an ore loading operation in a quarry, the VOLVO EC290B LC will exceed your expectations and deliver maximum return on investment.

Contact Us

For real-time quotes for new/used VOLVO EC290B LC excavators, attachment customization, bulk purchase discounts, or rental fleet solutions, contact our dedicated foreign trade sales team. We offer flexible payment terms (LC, TT, DP) to meet the financial needs of clients in different markets. Our team of export specialists will provide you with comprehensive support from equipment selection to door-to-door delivery, ensuring a smooth and hassle-free purchasing experience. For clients interested in becoming VOLVO authorized dealers, we offer attractive partnership programs with exclusive regional rights, marketing support, and technical training.