HITACHI ZX350H-3G

Short Description:

Product Detail Page: HITACHI ZX350-3G Hydraulic Excavator (For Foreign Trade)Bra...

Product Detail

Product Tags

Product Detail Page: HITACHI ZX350-3G Hydraulic Excavator (For Foreign Trade)

Brand & Model

Brand: HITACHI (Hitachi Construction Machinery) – A leading Japanese manufacturer of construction equipment with decades of expertise in precision engineering and hydraulic technology. Hitachi excavators are celebrated globally for their fuel efficiency, structural durability and intelligent control systems, and the ZX350 series stands out in the 35-ton heavy excavator segment for its exceptional performance in mining, quarrying and large-scale earthmoving projects. The brand’s global after-sales network covers over 190 countries, ensuring timely support for overseas users in harsh working environments.Model: HITACHI ZX350-3G (including ZX350H-3G/ZX350K-3G variants) – A 35-ton class heavy-duty hydraulic excavator tailored for mining and large-scale construction applications. Powered by the Isuzu AA-6HK1XQA direct-injection engine and paired with the HIOS hydraulic system, it delivers a rated power of 184kW (250PS) and a maximum bucket digging force of 237kN. With reinforced undercarriage and mine-specific front-end attachments, it excels in high-intensity operations such as open-pit mining, rock excavation and infrastructure construction, and is particularly popular in emerging markets like Africa, Southeast Asia and South America.

Core Advantages

1. High-Efficiency Power & Hydraulic System

The ZX350-3G is equipped with the Isuzu AA-6HK1XQA 6-cylinder direct-injection turbocharged engine (displacement 7.79L), which balances high power output with low fuel consumption. The engine features a robust cooling system and dust-resistant air filtration, enabling stable operation in extreme temperatures (from -20°C to 50°C) and dusty mining environments. Paired with the HIOS hydraulic system (variable axial piston pumps ×2 + gear pump ×1) with a main relief pressure of 34.3MPa, the excavator achieves seamless coordination between power and hydraulic control, reducing cycle times by 15% compared to previous models. The intelligent power mode (ECO/Heavy) allows operators to switch between fuel-saving and high-performance modes based on job requirements, cutting fuel costs by up to 10%.

2. Reinforced Durability for Harsh Working Conditions

Hitachi has significantly upgraded the ZX350-3G’s structural components to withstand mine-grade operations:

- Undercarriage Enhancement: The X-shaped crossbeam of the track frame has its strength increased by 45%, and sealed lubricated track pins reduce wear, extending undercarriage service life by 50%. Full track guards prevent rock damage to the undercarriage, ideal for rocky terrain in quarries.

- Front-End Work Device: Mine-specific reinforced boom and arm adopt WC spraying technology at the bucket link and pin connections, improving wear resistance by 30%. The standard rock bucket (1.5-1.8m³) is made of high-strength wear-resistant steel, capable of handling hard rock and gravel excavation.

- Heavy-Duty Body Structure: The upper frame uses thickened high-tensile steel plates with robot welding, enhancing torsion resistance and impact durability for long-term high-load operations.

3. Comfortable & Safe CRES Cab

The CRES (Cab with Roll-Over Protective Structure) cab is designed for operator safety and comfort:

- Low Vibration & Noise Reduction: The cab is mounted on anti-vibration rubber mounts, reducing vibration by 20% and keeping interior noise below 72dB, minimizing operator fatigue during 10+ hour shifts.

- Climate Control & Ergonomics: Equipped with a full-automatic air conditioner (cooling capacity 7.5kW) and an adjustable suspension seat, the cab adapts to extreme temperatures in tropical and desert regions. The 7-inch color monitor displays real-time engine/hydraulic data and fault codes, with multilingual support for global operators.

- Safety Features: Ultra-wide visibility with slim cab pillars, rearview camera (optional) and anti-slip maintenance platforms ensure safe operation in crowded construction sites and mining areas.

4. Low Maintenance Costs & Easy Serviceability

The ZX350-3G is engineered for minimal downtime and maintenance costs:

- Extended Service Intervals: Engine oil filter replacement every 500 hours, hydraulic oil filter every 2000 hours, and track link lubrication every 1000 hours (doubled from conventional models).

- Ground-Level Access: Daily checkpoints (fuel water separator, hydraulic oil level, coolant) are accessible from ground level, eliminating the need for climbing and reducing maintenance time by 25%.

- Long-Life Components: The fuel tank (500L) and hydraulic system (243L) use corrosion-resistant materials, and the engine oil sump is reinforced to prevent damage from rough terrain.

Detailed Real Shots (Showcasing Equipment Status)

① Overall Appearance: Robust & Mine-Ready

With transport dimensions of 11000mm×3190mm×3290mm and a rear swing radius of 3390mm, the ZX350-3G balances maneuverability with stability for narrow mine sites. The anti-corrosion paint and reinforced counterweight resist salt spray in coastal mining areas and sand abrasion in desert regions. The full track guards protect the undercarriage from rock impacts, a key feature for quarrying operations.

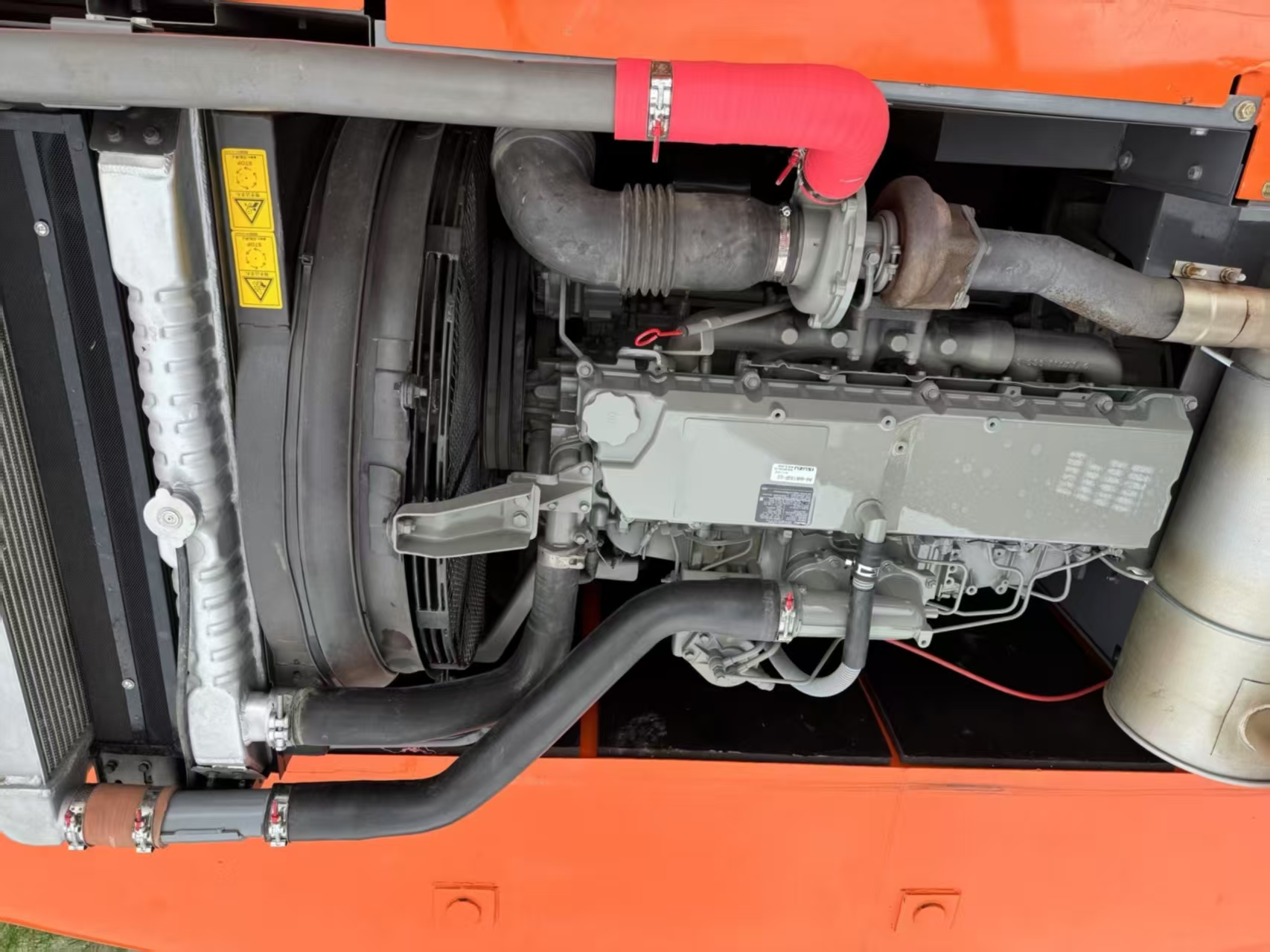

② Engine & Hydraulic System: Reliable & Efficient

The Isuzu AA-6HK1XQA engine and HIOS hydraulic system are neatly arranged in a sealed engine compartment with a large-capacity radiator for efficient heat dissipation. The hydraulic pipelines use reinforced connectors to prevent oil leakage, and the air intake system features a double-layer filter for dust resistance—critical for mining in Africa and Southeast Asia.

③ Boom & Bucket: Wear-Resistant & High-Performance

The 1.5-1.8m³ rock bucket (equipped with replaceable teeth) delivers a digging force of 237kN, capable of breaking through hard rock formations. The WC-sprayed pin connections on the arm and bucket reduce wear, extending service life in rock excavation. With a maximum digging depth of 7380mm and unloading height of 7240mm, it meets the demands of deep mine pit excavation and high-truck loading.

④ Cab & Controls: Intuitive & Comfortable

The CRES cab features an ergonomic joystick, shock-absorbing seat and 8-speaker audio system, reducing operator fatigue during long shifts. The color monitor displays real-time data (engine speed, hydraulic pressure, fuel level) and supports one-click fault diagnosis, while the large front/rear windows provide 360° visibility for safe operation in busy mining sites.

Typical Application Scenarios

The HITACHI ZX350-3G, with its mine-grade durability and high productivity, is ideal for large-scale overseas engineering projects:

- Open-Pit Mining & Quarrying: Specialized in surface soil stripping, ore loading and rock crushing in gold, copper and coal mines. The reinforced undercarriage and wear-resistant bucket handle rocky terrain, while the fuel-efficient engine cuts operational costs for 24/7 mining operations.

- Large-Scale Earthmoving & Infrastructure: Suitable for highway construction, dam building and port expansion. The HIOS hydraulic system ensures fast cycle times for bulk earthmoving, and the stable chassis enables safe operation on uneven construction sites.

- Demolition & Rock Excavation: Equipped with hydraulic breakers or grapples, it can handle building demolition and rock splitting in urban renewal projects or mountainous terrain. The precise hydraulic control allows for accurate operation in confined spaces.

Foreign Trade Service Guarantee

We offer comprehensive cross-border support for overseas buyers of the HITACHI ZX350-3G, covering the entire procurement lifecycle:

- Comprehensive Equipment Inspection: For used ZX350-3G units, we provide detailed test reports (engine power, hydraulic pressure, track wear, working hours) and real-time operation videos. Third-party inspection (SGS/BV) is available to verify equipment condition for international buyers.

- Customized Compliance Support: We assist in preparing import documents (CO, emission certificates, customs clearance papers) tailored to local regulations in Africa, Southeast Asia and South America. The ZX350-3G meets non-road emission standards for most emerging markets, ensuring smooth customs clearance.

- Logistics & On-Site Commissioning: We offer Ro-Ro shipping, container transport or bulk cargo solutions with anti-rust/anti-collision packaging. Professional technicians can be dispatched to the job site for equipment assembly, commissioning and operator training.

- Global Spare Parts & After-Sales: Leveraging Hitachi’s global parts network, common spare parts (filters, bucket teeth, hydraulic hoses) are available for delivery within 7-20 days to overseas sites. We provide a 1-year free parts warranty and 24/7 online technical support, with local service partners in key markets for on-site maintenance.

Why Choose HITACHI ZX350-3G?

The HITACHI ZX350-3G combines Hitachi’s precision engineering with mine-grade durability, making it a top choice for heavy-duty overseas projects. Its Isuzu engine and HIOS hydraulic system deliver unbeatable efficiency and fuel savings, while the reinforced undercarriage and wear-resistant components ensure long-term reliability in the harshest working conditions. For mining and construction companies in Africa, Southeast Asia and South America, the ZX350-3G offers a high return on investment with low downtime and maintenance costs—ideal for 24/7 high-intensity operations.

Contact Us

If you need detailed technical parameters of the ZX350-3G (e.g., climbing capacity, ground pressure), real-time quotes for new/used units, customized mine-specific attachments, or spare parts procurement channels, contact our team now. Let the HITACHI ZX350-3G power your overseas mining and construction projects with unmatched performance and durability!

Leave Your Message

Write your message here and send it to us