CAT 340GC

CAT 340GC 40-Ton Heavy-Duty Crawler Excavator – Foreign Trade Sales Copy (Revised Edition)

Brand & Model Positioning

Brand: CAT (Caterpillar)

Caterpillar, a global heavy equipment manufacturing leader with over 90 years of industry expertise, is known for “Unmatched Durability, Advanced Technology, and Global Service Excellence.” As the world’s top construction equipment brand, CAT serves 190+ countries through 2,000+ authorized dealers, ensuring 98%+ equipment uptime and 24/7 after-sales support. It pioneers engine and hydraulic system innovation, integrating cutting-edge technology with rugged components to create machinery that excels in extreme conditions—from mining and infrastructure to urban construction and disaster relief. Its focus on total cost of ownership, operator productivity, and sustainability has made it the gold standard for contractors, mining companies, and government agencies worldwideCat.

Model: CAT 340GC

The CAT 340GC is a 40-ton class heavy-duty crawler excavator from CAT’s GC (General Construction) series, designed for large-scale construction, mining, infrastructure development, and heavy lifting projects. It combines the powerful CAT C9.3B engine with an advanced load-sensing hydraulic system, balancing exceptional digging force, fuel efficiency, and operational precision. Its reinforced structure, extended service intervals, and intelligent technologies (Grade, Payload, Swing Assist) make it ideal for high-volume earthmoving, deep trenching, rock excavation, and material handling. Built for reliability and low maintenance in demanding environments, it is the preferred solution for global customers needing a high-productivity, cost-effective excavator for large-scale and heavy-duty projectsCat.

Core Technical Specifications

1. Basic Parameters

- Operating Weight: 39,000–39,900 kg (85,980–87,960 lbs) – ensures stability during heavy digging and lifting.

- Standard Bucket Capacity: 1.8–2.27 m³ (optional 1.5–2.8 m³ buckets for diverse applications).

- Overall Dimensions: Total length 11,200 mm × Total width 3,340 mm × Total height 3,450 mm – robust build for heavy-duty tasks.

- Track Gauge: 2,740 mm; Track Shoe Width: 600 mm – optimized ground pressure for stability on uneven terrain.

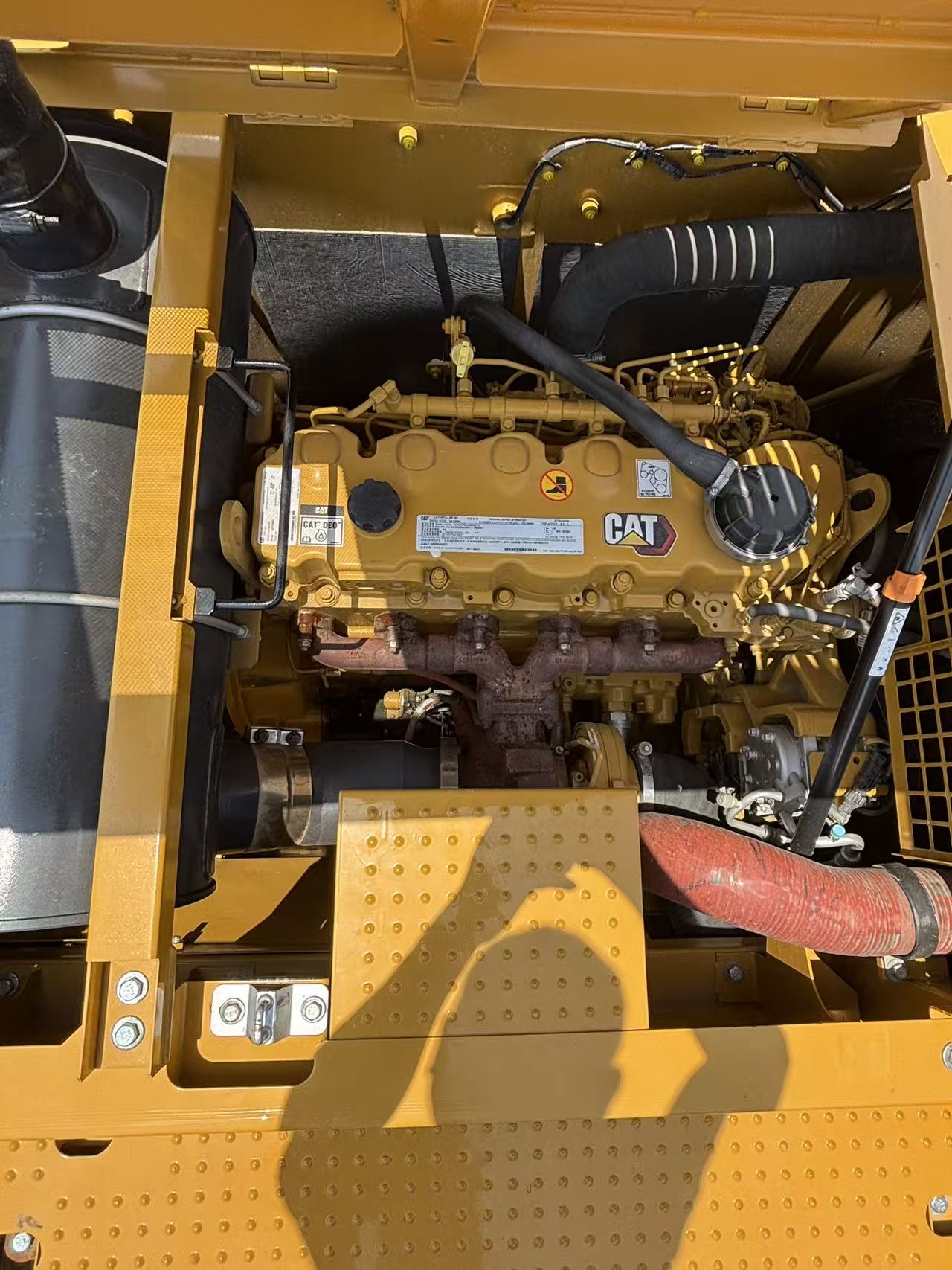

2. Engine Performance

- Engine Model: CAT C9.3B 6-cylinder in-line water-cooled diesel engineCat.

- Rated Power: 258.3 kW (346 HP) @ 1,800 rpm – reliable power for heavy operations.

- Displacement: 9.3 L – high power-to-weight ratio with optimized combustion efficiency.

- Emission Compliance: U.S. EPA Tier 4 Final, EU Stage V, Japan 2014 – eco-friendly operation meeting global standardsCat.

- Fuel Efficiency: 22–28 L/h under medium load – 10–15% lower fuel consumption than peer models, saving $2,000–$2,800 annually (based on 2,000 working hours/year)Cat.

- Environmental Adaptability: Cold-start capability at -18°C; high-ambient temperature tolerance up to 52°C; operation at 4,500 m altitudeCat.

- Maximum Torque: 1,800 Nm @ 1,400 rpm – strong low-end torque for efficient digging in compacted soil and rockCat.

3. Working Device & Excavation Performance

- Operating Range: Maximum digging radius 11,200 mm; maximum digging depth 7,510 mm; maximum dumping height 7,080 mm; maximum digging height 10,500 mm.

- Digging Force: Bucket digging force 210 kN; arm digging force 166 kN – penetrates hard rock and compacted soil with ease.

- Boom & Arm: Standard 6.5 m boom + 3.2 m arm; reinforced with high-strength steel and thick plating for heavy-duty applications.

- Attachment Compatibility: Supports hydraulic breakers (180–210 mm), grapples, augers, and rippers for demolition, mining, and site preparation.

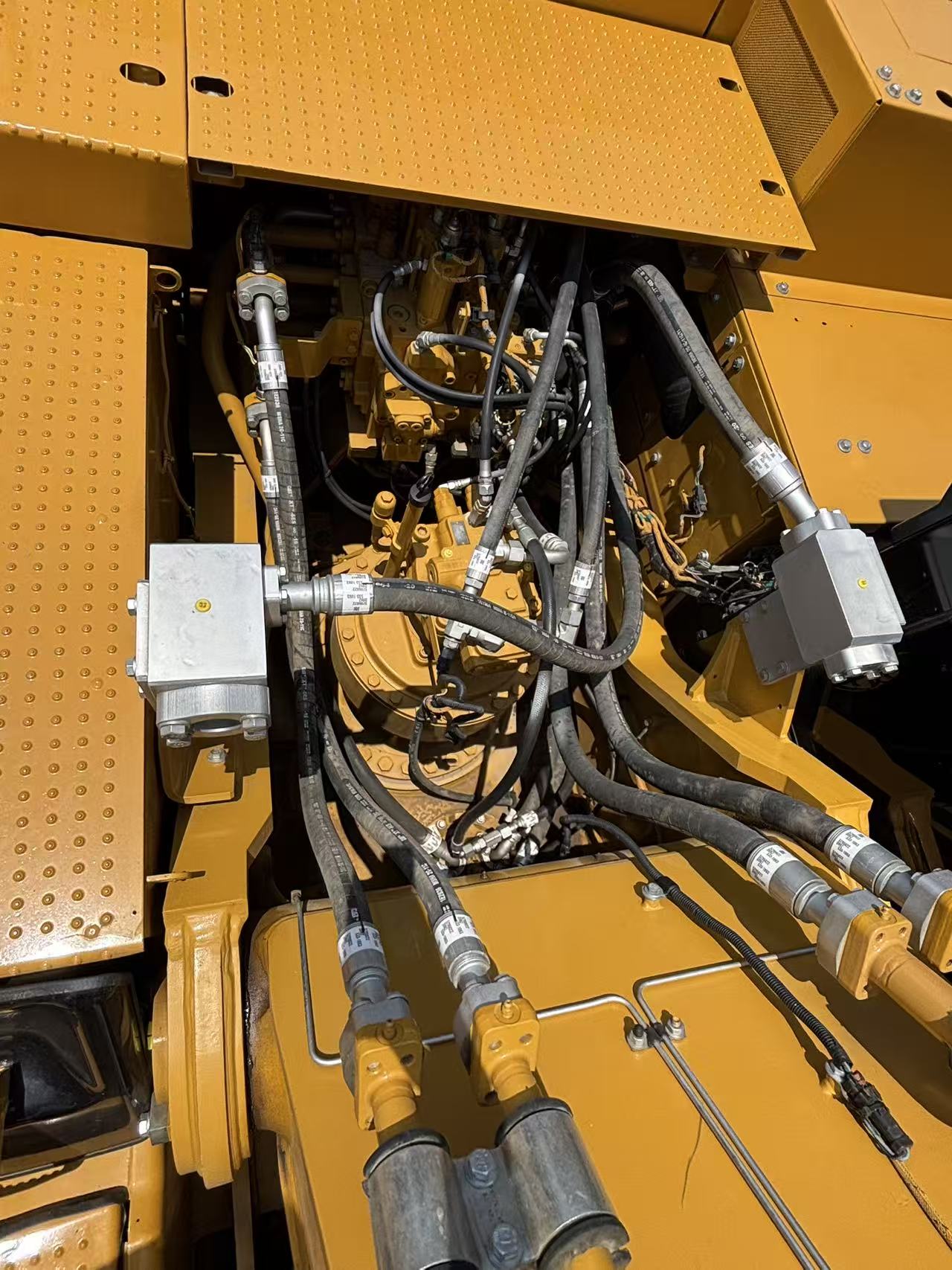

4. Hydraulic System

- System Type: Closed-center load-sensing hydraulic system with 3 power modes (Power, Smart, Eco) for precise control and efficiencyCat.

- Maximum Flow Rate: Total main pump flow 558 L/min (2×279 L/min); pilot pump flow 45 L/min.

- Relief Valve Pressure: 35 MPa (main hydraulic circuit); 38 MPa (lift mode); 28 MPa (swing circuit).

- Swing System: Axial piston motor with holding brake; swing speed 8.8 rpm; swing torque 143 kNm – smooth rotation for accurate truck loading.

- Travel System: Heavy-duty crawler undercarriage; travel speed 3.5 km/h (low)/5.5 km/h (high); maximum traction 450 kN for 45% slope climbing.

5. Undercarriage & Structural Design

- Undercarriage Type: Reinforced heavy-duty crawler chassis with extended track gauge (2,740 mm) and durable track shoes – absorbs impact and ensures stability in rough terrain.

- Track Configuration: Standard 600 mm track shoes; optional 700–900 mm shoes for low ground pressure in soft soil.

- Counterweight: 8,500 kg – enhances lifting capacity and balance during heavy loads.

- Protective Design: Boom/arm cylinder guards, sealed fuel/oil filters, and ground-level S∙O∙S ports for easy maintenance and component protectionCat.

6. Operator Cab & Safety

- Cab Certification: ROPS/FOPS Level II certified – meets global safety standards for rollover and falling object protectionCat.

- Ergonomic Design: Spacious cab with air-suspension seat, lumbar support, and low-effort joysticks – reduces operator fatigue during 12+ hour shifts.

- Control System: 10” color LCD display with real-time data (engine speed, fuel level, fault codes) and optional Grade Assist, Swing Assist, and Payload weighingCat.

- Comfort Configuration: Automatic climate control, sound insulation (≤72 dB(A)), and 360° visibility with rearview camera and side mirrors – minimizes blind spotsCat.

- Safety Features: Emergency stop button, travel alarm, anti-slip steps, and handrails – ensures safe entry/exit and operationCat.

7. Fuel & Fluid Capacities

- Fuel Tank Capacity: 600 L – supports 21–27 hours of continuous operation, reducing refueling frequency.

- Hydraulic Oil Tank Capacity: 161 L – efficient cooling system maintains stable oil temperature.

- Engine Oil Capacity: 32 L; Coolant Capacity: 40 LCat.

Core Advantages

1. High Productivity & Intelligent Technology

The CAT 340GC boosts productivity by 10–45% with optional CAT Grade (2D/3D), Swing Assist, and Payload weighing systems, ensuring precise grading and load targets. The Smart power mode automatically adjusts engine/hydraulic power to digging conditions, maximizing efficiency while saving fuelCat.

2. Exceptional Fuel Efficiency & Low Operating Costs

The CAT C9.3B engine with optimized combustion and 1,000-hour service intervals (oil/fuel filters) reduces downtime and maintenance costs by 30% over 10,000 hours compared to competitors. Eco mode lowers engine speed to 1,500 rpm, minimizing fuel consumption during light loadsCat.

3. Unmatched Durability & Reliability

Reinforced structural components, heavy-duty undercarriage, and high-dust capacity air filters ensure long service life in extreme conditions (high temperature, cold, altitude, dust). Auto hydraulic warmup in cold temperatures prolongs component life and reduces startup timeCat.

4. Operator-Centric Comfort & Safety

The ROPS/FOPS certified cab, low-noise design (≤72 dB(A)), and intuitive controls enhance operator comfort and reduce fatigue, improving productivity by 15% during long shifts. The 360° visibility and rearview camera minimize accident risks by 25% compared to conventional excavatorsCat.

5. Global Service & Support

CAT’s global network of 2,000+ dealers ensures 24/7 access to genuine parts and professional service in 190+ countries. Remote diagnostics via Product Link™ and on-site maintenance maximize uptime, while S∙O∙S ports simplify fluid analysis for proactive maintenanceCat.

Typical Application Scenarios

1. Large-Scale Construction & Infrastructure

- Foundation excavation for high-rise buildings, bridges, and dams.

- Trenching for long-distance water, gas, and oil pipelines.

- Material loading for concrete batching plants and aggregate quarries.

2. Mining & Quarry Operations

- Rock excavation and loading in limestone, granite, and coal mines.

- Overburden removal and site preparation for open-pit mining projects.

- Crushing and screening support in aggregate processing plants.

3. Demolition & Reconstruction

- Demolition of industrial buildings, bridges, and large structures.

- Concrete breaking and debris removal for urban renewal projects.

- Site clearance for power plants and industrial complexes.

4. Rental Fleet & Heavy Construction

Ideal for rental companies serving large contractors and government agencies. High demand for long-term infrastructure projects ensures stable returns and strong resale value.

5. Disaster Relief & Emergency Response

- Debris removal after earthquakes, floods, and hurricanes.

- Land reclamation and flood control in disaster-stricken areas.

- Rapid site preparation for temporary shelters and medical facilities.

Foreign Trade Service Guarantee

1. Customization Options

- Track Solutions: Standard 600 mm track shoes or 700–900 mm low-ground-pressure shoes for soft soil.

- Climate Packages: Cold-climate package (engine heater, battery warmer) for -30°C regions; hot-climate package (high-capacity AC, enhanced cooling) for 52°C marketsCat.

- Cab Configurations: Enclosed cab with heating/AC or open canopy for extreme environmentsCat.

- Multilingual Documentation: Operation manuals and parts catalogs in English, Spanish, Arabic, French, Russian, Chinese, etc.

2. Inspection & Certification

- Pre-Shipment Inspection: Rigorous checks by CAT or third-party institutions (SGS, BV) to ensure quality and compliance.

- Export Certifications: CE for EU, EPA Tier 4 Final for North America, Tier 2 emission reports, CO, commercial invoice, packing list, and bill of lading.

- Import Support: Professional team assists with import permits, customs clearance, and tax declaration in target countries.

3. Warranty & Training

- Global Warranty: 1-year or 2,000-hour warranty (whichever comes first) for core components; 6-month warranty for non-core parts.

- Free Training: On-site/online operator and maintenance training in local languages, covering safe operation, maintenance, and technology features (Grade, Payload).

4. Spare Parts & After-Sales

- Global Parts Supply: CAT’s parts network ensures delivery within 2–5 days in major markets and 5–10 days in remote areas.

- Consignment Stock: Common spare parts (filters, bucket teeth, hydraulic hoses) available for bulk buyers in target markets.

- On-Site Service: Optional maintenance contracts including regular inspections, fluid analysis, and on-site repairs to maximize uptime.

Why Choose CAT 340GC?

The CAT 340GC 40-ton crawler excavator combines CAT’s legendary durability with advanced technology, delivering unmatched productivity, fuel efficiency, and reliability. Its heavy-duty design excels in mining, infrastructure, and large-scale construction, while intelligent features and versatile attachments meet diverse application needs. Backed by CAT’s global service network, it offers low total cost of ownership and high investment returns. Whether you’re a mining company, construction giant, or rental fleet operator, the CAT 340GC is your ultimate solution for heavy-duty projects worldwide.

Contact Us

For real-time quotes on new/used CAT 340GC excavators, attachment customization, bulk discounts, or rental solutions, contact our foreign trade team. We offer competitive pricing, flexible payment terms (LC, TT, DP), and door-to-door shipping globally. Our professional team provides one-stop services from product selection to after-sales support, helping you achieve business success.