Kalmar DRF450-60S5K 45-Ton Reach Stacker

Short Description:

Kalmar DRF450-60S5K 45-Ton Reach Stacker - Foreign Trade Sales CopyBrand & Model...

- Rated Load Capacity: 45,000kg (45 Ton)

- Operating Weight: Approx. 69,500kg

- Overall Dimensions (L×W×H): 11,230mm × 4,130mm × 4,780mm

- Engine Model: Volvo TAD1360VE

- Engine Configuration: 6-cylinder, 4-stroke, water-cooled, turbocharged, electronic injection

- Rated Power: 256kW / 2100rpm

- Rated Torque: 1751N·m / 1200rpm

- Emission Standard: EU Stage II

- Max Lifting Height: 15,100mm

- Max Travel Speed (Unloaded/Loaded): 25km/h / 21km/h

- Max Lifting Speed (Unloaded/Loaded): 420mm/s / 250mm/s

- Minimum Turning Radius: 8,000mm

- Spreader Lateral Shift Range: ±800mm

- Spreader Rotation Angle: ±105°/-195°

- Max Gradeability (Loaded): 32%

- Cab Noise Level: ≤72dB

- Steering System: Hydraulic power steering

- Safety Devices: Emergency braking system, overload protection device |

Product Detail

Product Tags

Kalmar DRF450-60S5K 45-Ton Reach Stacker - Foreign Trade Sales Copy

Brand & Model Positioning

Brand: Kalmar – A global leader in cargo handling solutions with over 70 years of expertise, specializing in port and intermodal equipment. Renowned for innovative engineering, extreme durability, and intelligent operational systems, Kalmar dominates the reach stacker market across ports, container yards, and logistics hubs in the Middle East, Southeast Asia, and Europe. Its equipment is trusted by top shipping lines and terminal operators for unmatched efficiency in heavy container handling.Model: Kalmar DRF450-60S5K – A flagship 45-ton heavy-duty reach stacker, engineered for high-intensity 20ft/40ft container stacking and handling operations. Equipped with a fuel-efficient Tier 4 Final-compliant engine and Kalmar’s proprietary SmartFleet telematics system, it delivers exceptional lifting capacity, stacking height, and operational flexibility, ideal for busy container terminals, inland depots, and intermodal logistics centers.

Core Technical Specifications

- Rated Lifting Capacity: 45,000kg (for 20ft containers at maximum reach); 30,000kg (for 40ft containers at extended reach)

- Stacking Performance: Max stacking height of 6+1 high for 40ft containers; maximum outreach of 6.0m; inner turning radius optimized for narrow container yard layouts

- Engine: Volvo Penta D13J Tier 4 Final diesel engine; rated power 338kW (460HP) @ 1,800rpm; peak torque 2,200N·m @ 1,200rpm; low fuel consumption and reduced emissions for eco-friendly operations

- Transmission & Travel: Dana Spicer TE-32 powershift transmission with 4 forward/4 reverse gears; max travel speed 25km/h; gradeability ≥35% for steep yard ramps

- Maneuverability: Minimum outer turning radius 10.5m; 4-wheel steering system (selectable 2-wheel/4-wheel/crab steering modes) for flexible operation in tight spaces

- Overall Dimensions: Length (without spreader) 11.2m; width 3.0m; height (cab top) 4.2m; wheelbase 5.5m

- Weight & Undercarriage: Operating weight ≈85,000kg; heavy-duty axles with load-sharing suspension; 16.00-25 28PR super-elastic tires for reduced ground pressure and long service life

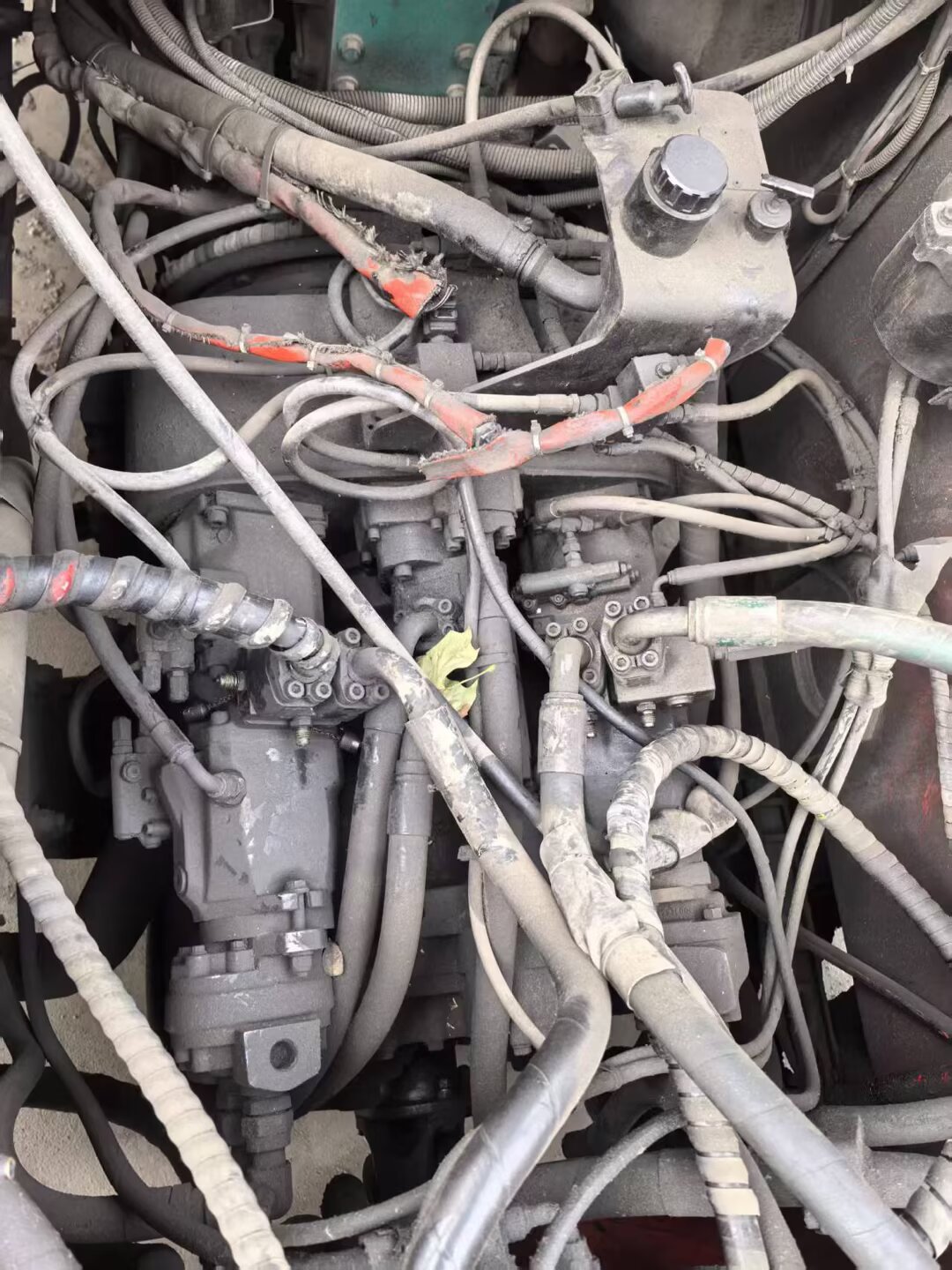

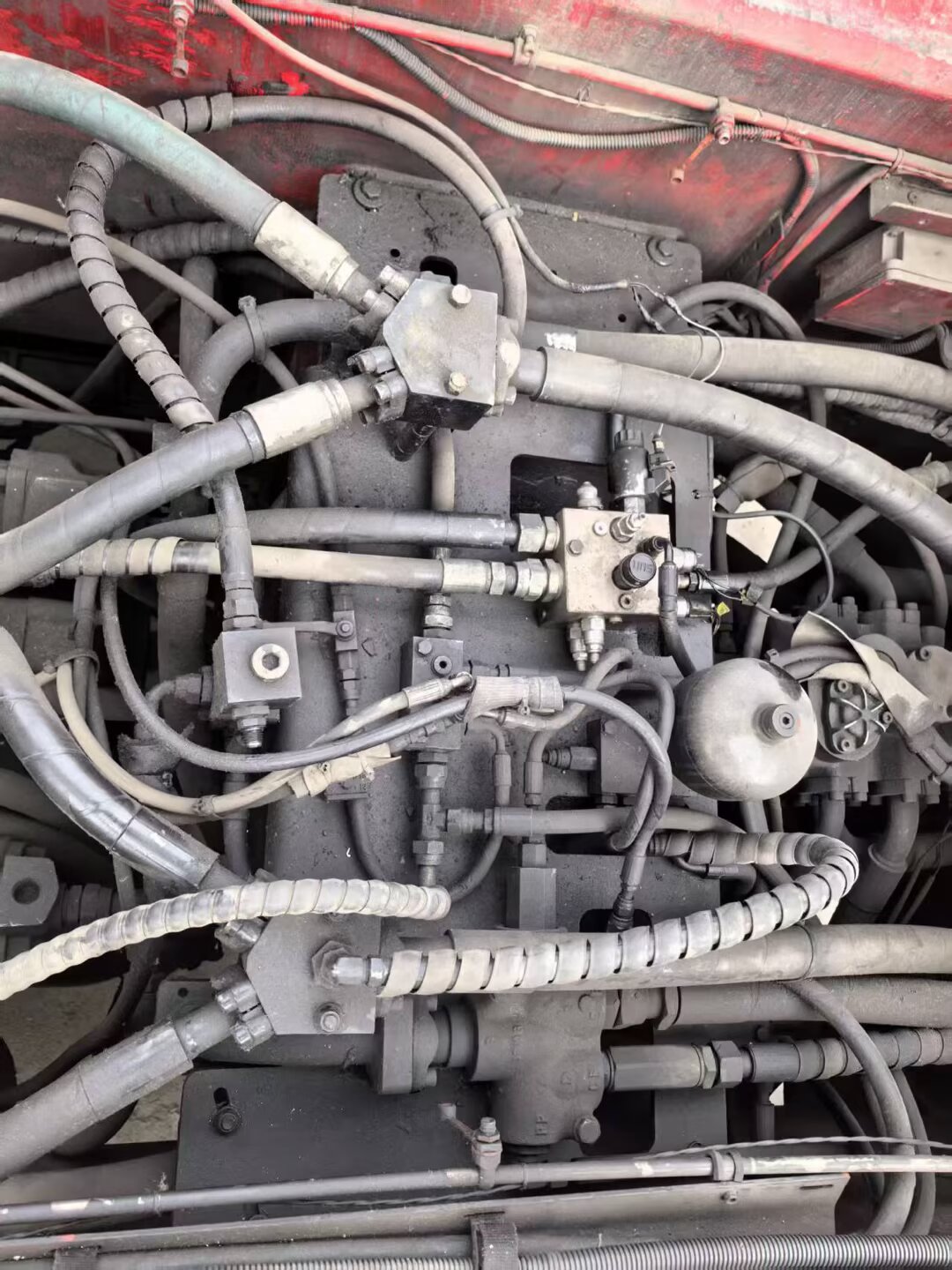

- Hydraulic System: Load-sensing variable displacement hydraulic system; working pressure 35MPa; fast and precise boom extension/retraction and container lifting/lowering

- Operator Cab: ROPS/FOPS certified; fully enclosed with air conditioning and heating; ergonomic joystick controls; large panoramic windows and rearview cameras for 360° visibility

Core Advantages

1. Unmatched Heavy-Load Handling & Stacking Efficiency

- 45-Ton Lifting Capacity: Easily handles fully loaded 20ft containers and standard 40ft containers, with a 6+1 stacking height that maximizes vertical storage space in container yards, reducing land use costs by 25% compared to lower-stacking models.

- Extended 6.0m Outreach: Enables safe handling of containers stacked two rows deep, eliminating the need for additional yard shunters and boosting terminal throughput by 20%.

- Multi-Steering Modes: 2-wheel steering for long-distance travel, 4-wheel steering for tight turns, and crab steering for lateral movement—adapting to diverse yard layouts and operational needs.

2. Fuel Efficiency & Intelligent Operation

- Volvo Penta Tier 4 Final Engine: Delivers high power output with low fuel consumption (18-22L/h during heavy operation), 15% more efficient than comparable models. The engine’s aftertreatment system meets strict emission standards, suitable for eco-sensitive port areas.

- Kalmar SmartFleet Telematics: Real-time monitoring of fuel consumption, machine performance, and operator behavior; remote diagnostics to reduce downtime; fleet management tools to optimize scheduling and maintenance plans.

- Load Moment Indicator (LMI): Integrated safety system that continuously monitors lifting load, boom angle, and outreach; automatic alarm and load limitation when approaching safety thresholds, preventing overloading accidents.

3. Operator Comfort & Safety

- Premium Ergonomic Cab: Spacious interior with adjustable air suspension seat, climate control system, and low-noise design (≤75dB(A))—reducing operator fatigue during 12-hour shifts. The joystick controls are positioned for effortless operation, minimizing arm and shoulder strain.

- 360° Visibility Solution: Panoramic cab windows, rearview cameras, and a reversing radar system eliminate blind spots, ensuring safe handling of containers in crowded yards. The cab’s elevated position provides a clear view of the stacking area and surrounding environment.

- Comprehensive Safety Features: Emergency stop buttons on both cab and chassis; automatic parking brake; anti-slip steps and handrails for safe cab access; fire suppression system as an optional upgrade for high-risk environments.

4. Durability & Low Maintenance Costs

- Heavy-Duty Structural Design: The boom, chassis, and spreader are made of high-strength Swedish steel, with reinforced welding at stress points—withstanding the harsh conditions of 24/7 port operations and extending service life to 15,000+ hours.

- Simplified Maintenance Access: All service points (engine filters, hydraulic components, battery) are centrally located and accessible from ground level; the engine hood and side panels open wide for easy inspection and repair; extended maintenance intervals (500 hours) reduce downtime and operational costs.

- Global After-Sales Support: Kalmar’s 200+ authorized service centers and 30 regional parts warehouses worldwide ensure fast delivery of spare parts (7-10 days for critical components); on-site technical support is available within 48 hours for major port hubs.

Typical Application Scenarios

- Container Terminals: High-volume stacking and handling of 20ft/40ft containers in seaports and river ports, optimizing yard storage density and throughput.

- Inland Depots: Intermodal container transfer between trucks, trains, and storage yards, supporting the seamless flow of cargo in supply chain networks.

- Logistics Hubs: Heavy-load container handling for large-scale distribution centers, especially those specializing in bulk goods, automotive parts, and industrial equipment.

- Railway Intermodal Yards: Loading and unloading containers from freight trains, with flexible steering modes adapting to railway siding layouts.

Foreign Trade Service Guarantee

- Customization Options: Optional automatic container spreader (for 20ft/40ft/45ft containers), fire suppression system, cold-climate package (engine block heater), and multilingual operator interface (English/Arabic/Spanish).

- Inspection & Certification: Pre-shipment SGS/BV third-party inspection; provision of Certificate of Origin (CO), CE certification, IMO emission compliance reports, and customized customs clearance documents for target markets.

- Warranty & Training: 2-year global warranty for core components (engine, transmission, hydraulic system); free on-site operator and maintenance training in local languages, covering safe operation, SmartFleet usage, and routine servicing.

- After-Sales Support: 24/7 online technical support via Kalmar’s global service portal; consignment stock service for bulk buyers (port authorities, shipping lines); remote diagnostics to resolve faults without on-site visits.

Why Choose Kalmar DRF450-60S5K?

The Kalmar DRF450-60S5K represents the gold standard in 45-ton reach stackers, combining Kalmar’s decades of port equipment expertise with cutting-edge technology. Its 45-ton lifting capacity, 6+1 stacking height, and intelligent telematics system solve the core pain points of container terminals—low throughput, high land costs, and inefficient fleet management. Backed by global after-sales support, it is the ideal choice for port operators and logistics enterprises seeking to maximize operational efficiency and return on investment.

Contact Us

For real-time quotes for new/used Kalmar DRF450-60S5K reach stackers, spreader customization, or SmartFleet telematics training programs, contact our dedicated sales team. We offer bulk order discounts and long-term maintenance contracts for port authorities, shipping lines, and intermodal logistics companies.

Leave Your Message

Write your message here and send it to us