CAT 320DL

Short Description:

Product Detail Page: CAT 320DL Crawler Excavator (For Foreign Trade)Brand & Mode...

- Operating Weight: 22270kg

- Bucket Capacity: 1m³

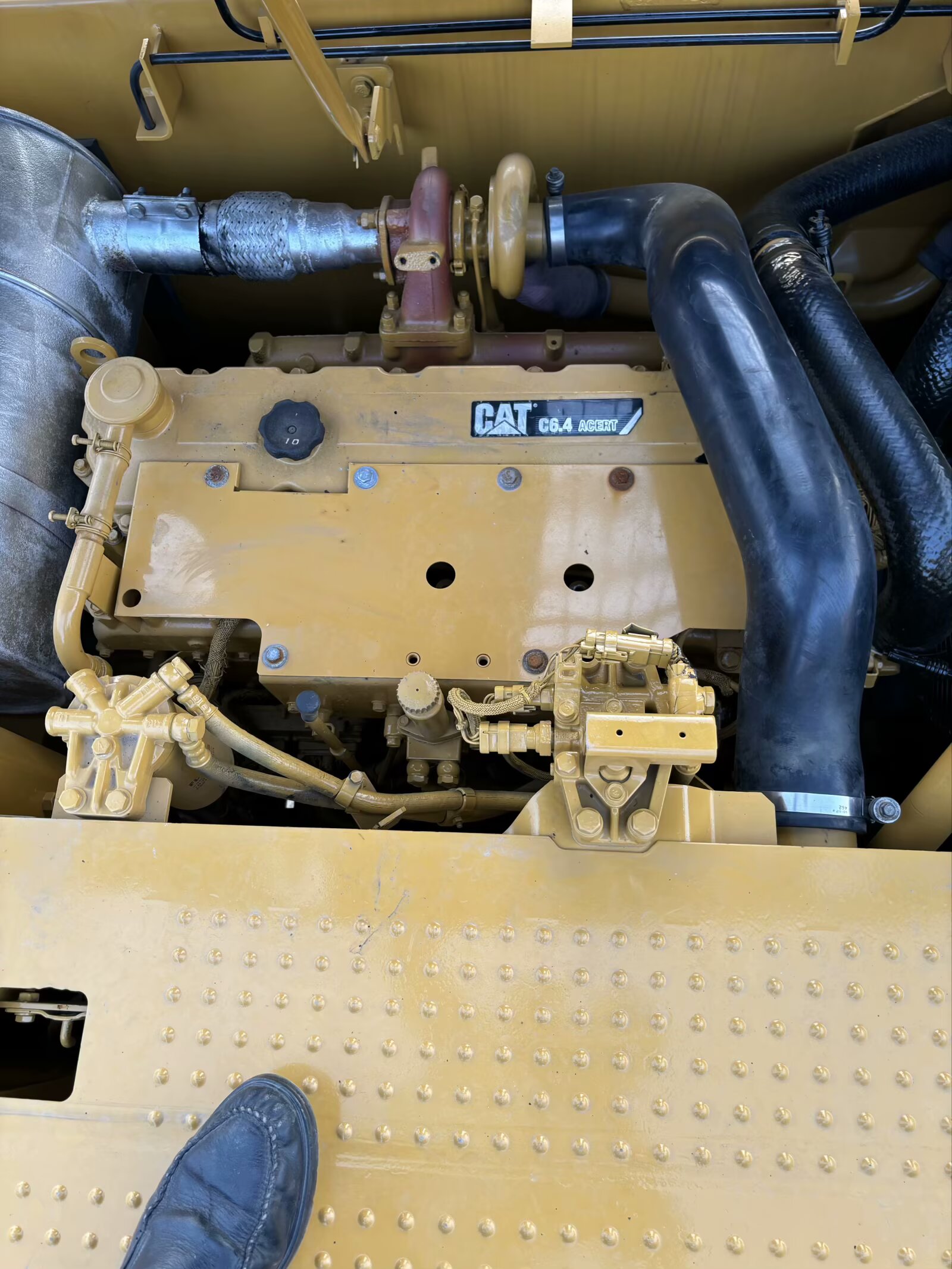

- Engine Model: Cat® C6.4 ACERT™

- Displacement: 6.37L

- Rated Power: 103kW / 2000rpm

- Bucket Digging Force: 140.1kN

- Arm Digging Force: 106.4kN

- Maximum Digging Depth: 6710mm

- Maximum Dumping Height: 6500mm

- Maximum Digging Radius: 9850mm

- Maximum Digging Height: 9840mm

- Swing Speed: 11.5rpm

- Total Transport Length: 9460mm

- Total Transport Width: 2800mm

- Total Transport Height: 3030mm

- Fuel Tank Capacity: 410L

- Hydraulic Tank Capacity: 120L

Product Detail

Product Tags

Product Detail Page: CAT 320DL Crawler Excavator (For Foreign Trade)

Brand & Model

Brand: CAT (Caterpillar) – A world - leading heavy machinery giant with unshakable influence in the global engineering equipment market. It has a complete global service network covering over 200 countries and regions, especially popular in high - demand markets such as Southeast Asia, Africa, and the Middle East. Its products are famous for extreme durability and stable performance in harsh working conditions like mines and deserts, and it provides fast spare parts supply and professional technical support for overseas users.Model: CAT 320DL – A star medium - tonnage crawler excavator in CAT’s D - series, positioned in the 20 - ton class. The “L” represents the extended chassis design, which enhances the stability and lifting capacity of the whole machine significantly. It integrates powerful power, efficient operation, and easy maintenance, and is a reliable choice for overseas medium - scale engineering projects such as construction, mining, and road construction, winning high recognition from global engineering teams.

Core Advantages

1. Powerful & Efficient Power System with Excellent Fuel Economy

It is equipped with the CAT C6.4 ACERT™ engine, with a displacement of 6.37L and a rated power of 103kW/2000rpm. The ACERT™ technology optimizes fuel delivery and air management, which not only meets global low - emission standards but also ensures strong power output. The engine has an automatic speed control function. When there is no load or light load, it can reduce the speed automatically to save fuel. The machine has a bucket digging force of 140.1kN and an arm digging force of 106.4kN, and the traction force can reach 206kN, which can easily handle hard materials such as gravel and weathered rock. The radial - sealed air filter with a double - layer filter element has high filtration efficiency, and the monitor will give an alarm when the dust accumulates excessively, effectively protecting the engine and prolonging its service life.

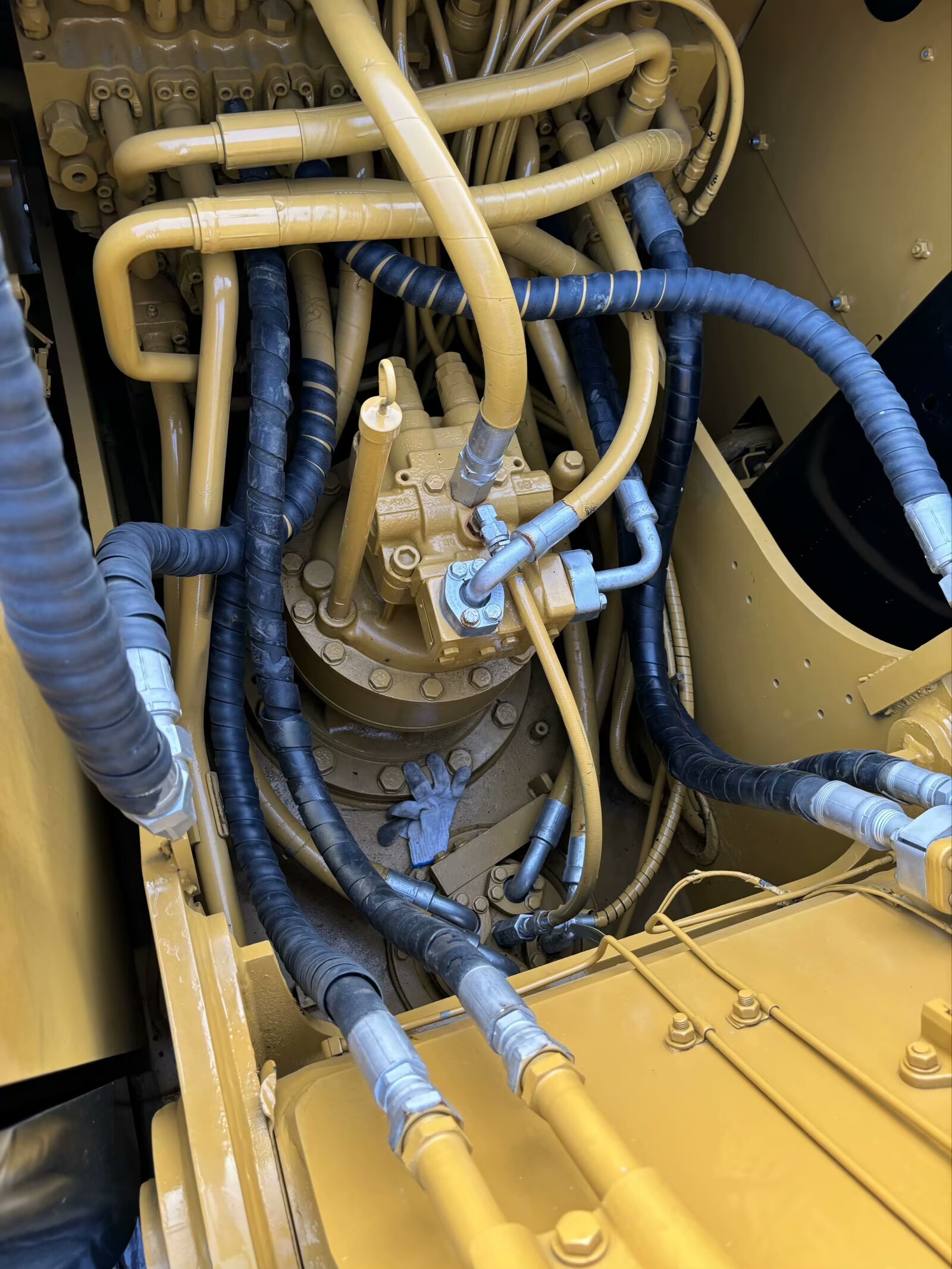

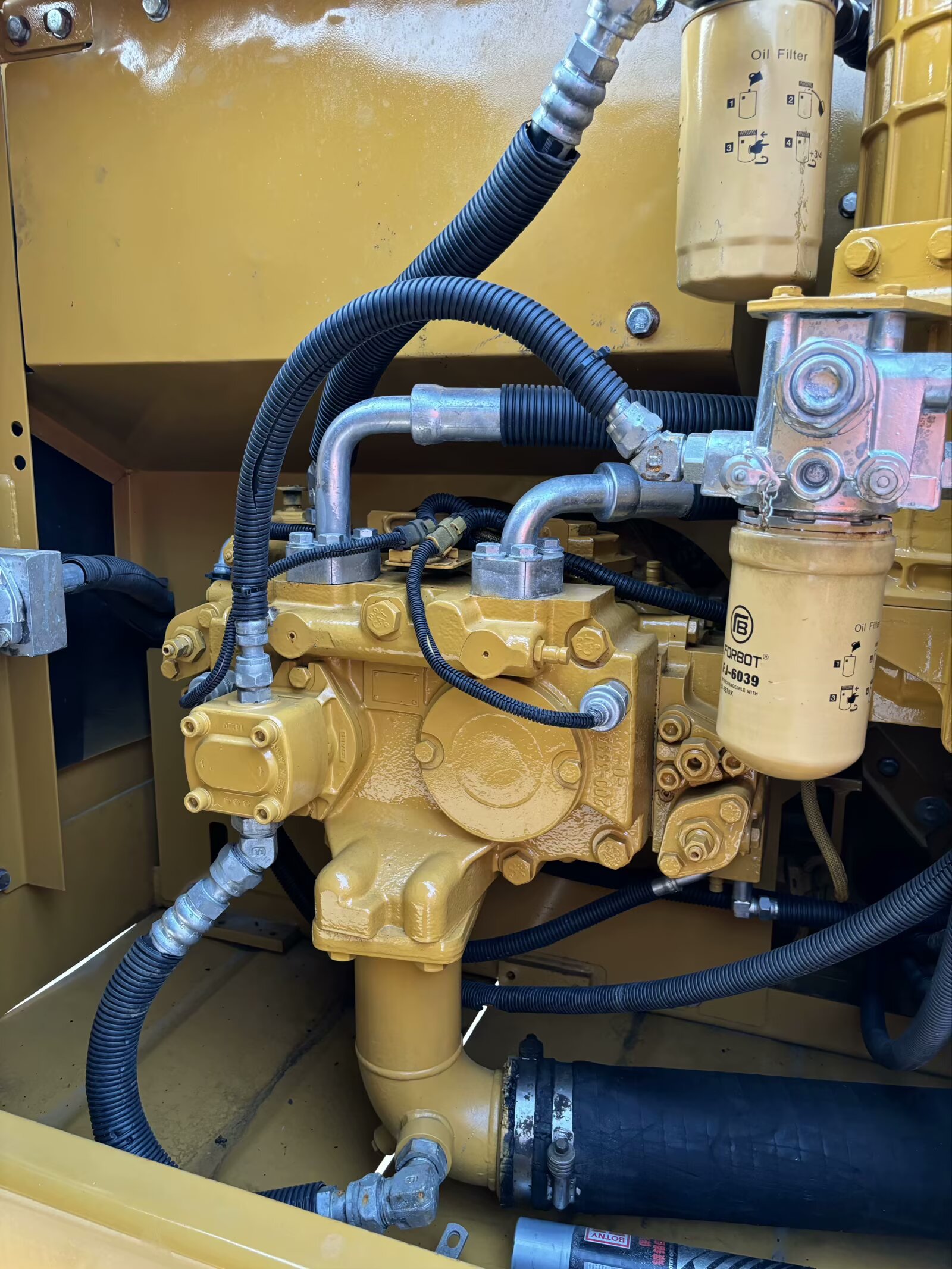

2. High - Performance Hydraulic System & Strong Operational Stability

The hydraulic system of the excavator has a maximum working pressure of 35MPa. The main pump, control valve, and hydraulic oil tank are arranged close to each other, which shortens the connecting pipeline, reduces pressure loss and friction loss, and improves system efficiency. The hydraulic interaction sensing system can make full use of the two hydraulic pumps, enabling the engine power to be fully exerted. The boom and arm regeneration circuit can save energy during the process of boom descending and arm retracting, reducing the operation cycle and improving production efficiency. The standard auxiliary hydraulic valve can be matched with high - pressure and medium - pressure attachments such as hydraulic hammers and crushing shears, which expands the application scope of the equipment.

3. Reinforced Chassis Structure & Strong Terrain Adaptability

The extended chassis design of the 320DL makes the overall operating weight reach 22270kg. The X - shaped box - section base and the robot - welded pentagonal track roller frame have excellent resistance to torsion and bending. The track grounding length is 3650mm, and the minimum ground clearance is 450mm. The 800mm wide track plate reduces the ground pressure, enabling the excavator to operate stably on uneven and gravel - covered ground without being easily trapped. All the track rollers, carrier rollers, and idlers are sealed and lubricated, which can adapt to long - term continuous operation in harsh working conditions such as mines and construction sites.

4. Humanized Cab & Convenient Maintenance

The cab is spacious and comfortable, with a low - noise design that reduces the fatigue of operators during long - time work. It is equipped with a color LCD graphic display that supports 27 languages including Chinese, and can display key data such as fuel level and hydraulic oil temperature in real - time. It can also send out alarm prompts for abnormal conditions such as low engine oil pressure. The operation buttons and levers are arranged scientifically, and the air - conditioning system and storage space are configured to create a humanized operating environment. The key maintenance parts are arranged centrally. The air filter and various filters are easy to replace, and the electronic diagnosis system can quickly locate faults, which is convenient for overseas operators to carry out daily maintenance and shorten the equipment downtime.

Detailed Real Shots (Showcasing Equipment Status)

① Overall Appearance: Solid and Stable

The overall transportation dimensions are 9460×2800×3030mm. The classic CAT yellow exterior is painted with anti - corrosion and anti - rust coatings, which can resist wind, sand, and rain erosion in outdoor environments. The extended chassis and heavy - duty counterweight (with a ground clearance of 1020mm) ensure the stability of the machine during lifting and heavy - load excavation, and the compact rear swing radius of 2750mm reduces the risk of collision in narrow spaces.

② Engine & Hydraulic System: Reliable and Efficient

The C6.4 ACERT™ engine runs smoothly with low vibration. The radiator is arranged on the side of the cab, which can discharge hot air and noise to the side away from the operator. The hydraulic pipelines are neatly arranged and have good sealing performance. The hydraulic cylinder buffer device at the end of the boom and arm can reduce vibration and noise during operation and extend the service life of the components.

③ Boom & Bucket: Sturdy and Wear - Resistant

The standard bucket capacity is 1m³, made of high - strength wear - resistant steel. The 5700mm long boom and 2900mm long arm can achieve a maximum digging depth of 6710mm and a maximum unloading height of 6500mm, which can meet the needs of most medium - scale excavation and loading operations. The key welding parts are reinforced to resist the impact of hard materials during excavation.

④ Cab & Controls: Comfortable and Intuitive

The cab has a wide field of vision, and the large - area glass windows reduce the operation blind spots. The ergonomic seat and easy - to - reach control levers make the operation more labor - saving. The control buttons such as the air conditioner are arranged on the right side of the cab for easy access. The instrument panel is clear and easy to read, allowing the operator to grasp the equipment operation status at a glance.

Typical Application Scenarios

The CAT 320DL, with its balanced performance, is widely used in various overseas medium - scale engineering projects:

- Mine and Quarry Operations: Suitable for surface soil stripping in small and medium - sized mines, loading ore and crushed stone, and cleaning mining waste. Its strong digging force and wear - resistant bucket can cope with the impact of hard rock, and the stable power system can adapt to long - time continuous operation.

- Construction Site Earthwork: It is used for foundation excavation, foundation pit backfilling, and construction material loading and unloading in the construction of commercial buildings, residential districts, and factories overseas. The extended chassis ensures stability during high - altitude operation, and the flexible operation can improve the efficiency of earthwork construction.

- Road and Municipal Engineering: It can be used for digging roadbed trenches, laying underground pipelines, cleaning road construction waste, and river dredging. Its low ground pressure will not damage the existing road surface, and the compact body can adapt to the narrow operation space in urban areas.

- Energy and Water Conservancy Projects: It is competent for the construction of small and medium - sized reservoirs, irrigation canal excavation, and auxiliary construction of wind power and hydropower stations. It can work stably in complex terrain such as hills and river valleys, and can be matched with special attachments to carry out multi - type operations.

Foreign Trade Service Guarantee

We provide one - stop cross - border procurement services for overseas users to eliminate their worries:

- Comprehensive Inspection Reports: Provide detailed test reports covering engine power, hydraulic system pressure, track wear, and other indicators. For used equipment, we will also attach complete maintenance records and working hour records, and provide real - time operation videos to let you know the equipment status clearly.

- Customized Customs Clearance Services: Our professional team is familiar with the import policies of various countries and regions. We can assist in preparing certificates of origin, emission reports, and other documents, calculate tariffs reasonably, and ensure that the equipment passes through customs smoothly in Southeast Asia, Africa, the Middle East, and other regions.

- Reliable Logistics and Commissioning: Provide flexible logistics solutions such as container and roll - on - roll - off shipping according to the user's needs. The equipment is packaged with anti - collision and anti - rust materials to avoid damage during transportation. After the equipment arrives, we can arrange technicians to carry out on - site commissioning and operator training.

- Global Spare Parts and After - Sales Support: Relying on CAT’s global service network, common spare parts such as filters, bucket teeth, and hydraulic hoses can be delivered to overseas construction sites quickly. We provide 24 - hour online technical support. If there is a fault, we can coordinate local service providers to carry out on - site maintenance and minimize downtime.

Why Choose CAT 320DL?

The CAT 320DL inherits CAT’s consistent high - quality manufacturing standards. The extended chassis design makes up for the lack of stability of ordinary medium - tonnage excavators, and the combination of the ACERT™ engine and the efficient hydraulic system achieves a balance between power and fuel economy. It solves the pain points of overseas users such as harsh working conditions, high maintenance costs, and diverse operation needs. With CAT’s strong brand influence and perfect global after - sales network, it is a low - risk investment choice for overseas engineering teams engaged in medium - scale operations.

Contact Us

If you want to obtain detailed parameters including maximum lifting capacity and turning radius, real - time inspection videos of used equipment, customized quotes for new and used machines, or spare parts procurement channels, please contact our team immediately. Let the CAT 320DL empower your overseas engineering projects and create higher operational value for you!

Leave Your Message

Write your message here and send it to us